Challenges:

To ensure warehouses operate in a normal status, workers need to perform equipment maintenance and repair on a regular basis. They physically inspect those equipment, write down reports, and then input them into the warehouse's backend platform via a fixed computer. It consumes time, is prone to errors and may exist employee fraud.

Solution:

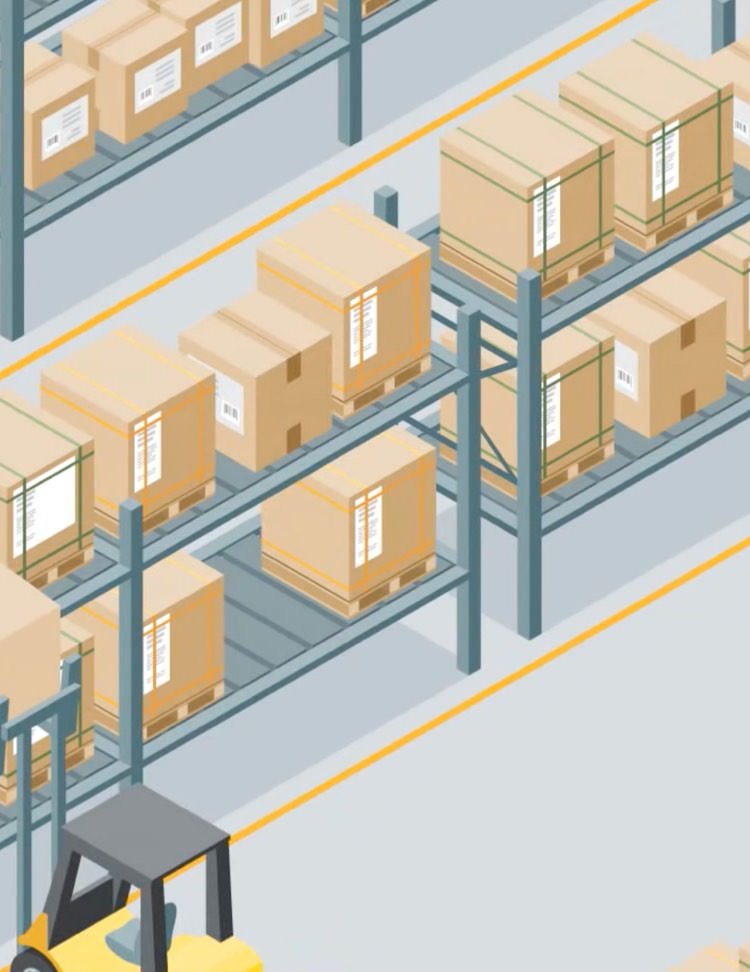

Every piece of warehouse equipment that need to be inspected is labeled with a RFID or barcode tags. It contains a unique serial number and the equipment information. In field service, field workers deploy Chainway handheld RFID readers or barcode scanners to identify those equipment, perform a maintenance and input the result into the warehouse management system under 3G/4G/Wi-Fi wireless connectivity.

Results:

1. Chainway handheld RFID readers / barcode scanner capture and transmit inspection and maintenance data accurately. It eliminates human errors in transcription.

2. With GPS, Chainway device sends field service location while inspectors working. It requires employees to be on-site, which helps the company fight against employee fraud.

3. Chainway handheld reader is equipped with a color camera. Inspectors can use it to add photos in the report. Maintenance data will be clearer.

To ensure warehouses operate in a normal status, workers need to perform equipment maintenance and repair on a regular basis. They physically inspect those equipment, write down reports, and then input them into the warehouse's backend platform via a fixed computer. It consumes time, is prone to errors and may exist employee fraud.

Solution:

Every piece of warehouse equipment that need to be inspected is labeled with a RFID or barcode tags. It contains a unique serial number and the equipment information. In field service, field workers deploy Chainway handheld RFID readers or barcode scanners to identify those equipment, perform a maintenance and input the result into the warehouse management system under 3G/4G/Wi-Fi wireless connectivity.

Results:

1. Chainway handheld RFID readers / barcode scanner capture and transmit inspection and maintenance data accurately. It eliminates human errors in transcription.

2. With GPS, Chainway device sends field service location while inspectors working. It requires employees to be on-site, which helps the company fight against employee fraud.

3. Chainway handheld reader is equipped with a color camera. Inspectors can use it to add photos in the report. Maintenance data will be clearer.