-

Our Products

Mobile Computers

Product Model- C66 Mobile Computer (Android 11/13)

- MC51 5G Mobile Computer (Android 14)

- C63 Mobile Computer (Android 13)

- MC51S Mobile Computer (Android 16)

- MC62 Mobile Computer (Android 13)

- MC95 Mobile Computer (Android 12)

- MC50 5G Mobile Computer (Android 12/14)

- MC21 Mobile Computer (Android 12)

- C61 Mobile Computer (Android 11/13)

- C61 Cold Storage Mobile Computer (Android 11/13)

- C90 Mobile Computer (Android 10/14)

- C6000 Mobile Computer (Android 10/13)

- C71 Mobile Computer (Android 11/13)

- C72 Mobile Computer (Android 11/13)

- C66 Wi-Fi Only (Android 11)

- C70 Mobile Computer (Android 11)

- C70 Mobile Computer with Thermometer

- C75 Mobile Computer with Printer

- C90A Mobile Computer (Android 14)

Mobile Computer (Android 11/13)

More Powerful, More Extensible, More Advanced in Every Way

5G Mobile Computer (Android 14)

Flagship Performance, Long-Term Value

Mobile Computer (Android 13)

The Flagship Keypad Handheld For Next-Level Industrial Data Capture.

Mobile Computer (Android 16)

High Performance on a Modern Platform, Engineered for the Enterprise.

Mobile Computer (Android 13)

Ergonomic Keypad and Scan Angle for Enhanced Work Performance.

Mobile Computer (Android 12)

A Practical Balance of Ruggedness Reliability, and Cost.

5G Mobile Computer (Android 12/14)

5G · Android 12/14 · IP67

Mobile Computer (Android 12)

Easier to Use, More Cost-Effective, Rugged and Durable

Mobile Computer (Android 11/13)

Easy and Flexible Data Entry, Remarkable Data Capture Performance

Cold Storage Mobile Computer (Android 11/13)

Superior Performance for Cold Chain Warehousing

Mobile Computer (Android 10/14)

Larger Display, Lighter Weight, Stronger Performance.

Mobile Computer (Android 10/13)

Rugged and Portable with High Performance

Mobile Computer (Android 11/13)

Fully Upgraded Performance, Versatile Functions Enabled

Mobile Computer (Android 11/13)

Ultimate Barcode Scanning, Powerful Battery, Easy to Hold

Wi-Fi Only (Android 11)

Enhanced Wi-Fi Performance, Designed for Indoor Applications

Mobile Computer (Android 11)

Ultra Thin & Light, Rugged Enough to Use Anywhere

Mobile Computer with Thermometer

High Precision Temperature Measurement in One Second

Mobile Computer with Printer

Mobile Efficient Receipt Printing

Mobile Computer (Android 14)

Larger Display, Lighter Weight, Stronger Performance.

Rugged Tablets

Product ModelAI 5G Industrial Tablet (Android 14)

Rugged Performance, Customized to Your Needs, Fueling Sustained Business Growth

Industrial Tablet (Android 14)

Next-Level Specs. Unstoppable Performance. All-Day Power. Effortless Experience.

RFID Tablet (Android 13)

8'' Screen & 8700mAh Battery, Abundant Functions Available

Industrial Tablet (Android 13)

More Power, More Features and More Versatility

Industrial Tablet (Android 9)

8'' Screen & 8000mAh Battery, Abundant Functions Available

RFID Tablet (Android 9)

Best-in-Class RFID Reading Performance

Handheld RFID Readers

Product Model- C72 UHF RFID Reader (Android 11/13)

- MC51 5G UHF RFID Reader (Android 14)

- MC51 5G Built-in RFID Reader (Android 14)

- C5 UHF RFID Reader (Android 11/13)

- C66 UHF RFID Reader (Android 11/13)

- SR160 UHF RFID Scanner

- C66 Built-in RFID Reader (Android 11/13)

- MC50 5G UHF RFID Reader (Android 12/14)

- C61 UHF RFID Reader (Android 11/13)

- C71 Built-in RFID Reader (Android 11/13)

- R7 UHF RFID Sled Reader

- R6 UHF RFID Sled Reader

- R2 Bluetooth RFID Reader

UHF RFID Reader (Android 11/13)

Best-in-Class UHF RFID Performance, Trusted by the Industry.

5G UHF RFID Reader (Android 14)

The New Benchmark in RFID Performance — Max Speed, Max Range, Max Accuracy.

5G Built-in RFID Reader (Android 14)

Breakthrough in Read Rates and Accuracy. Powerful RFID Now Fits Right in Your Pocket.

UHF RFID Reader (Android 11/13)

Stronger UHF Performance, Higher Security and Reliability

UHF RFID Reader (Android 11/13)

Larger Screen Display, Stronger UHF Performance

UHF RFID Scanner

UHF & Barcode in One Device. Lightweight, Ergonomic, Versatile.

Built-in RFID Reader (Android 11/13)

The Ultimate Compact and Lightweight Handheld RFID Reader

5G UHF RFID Reader (Android 12/14)

Chainway's Most Powerful Handheld RFID Reader, Setting New Standards for RFID Performance and Efficiency

UHF RFID Reader (Android 11/13)

Committed to Superior UHF Performance

Built-in RFID Reader (Android 11/13)

Lightweight and Portable, Superior UHF Capability

UHF RFID Sled Reader

Make Your Device a Pro RFID Terminal.

UHF RFID Sled Reader

Powerful UHF Reading and Writing

Bluetooth RFID Reader

Outstanding UHF Capability

Bluetooth RFID Readers

Product ModelBluetooth RFID Scanner

UHF & Barcode in One Device. Lightweight, Ergonomic, Versatile.

UHF RFID Sled Reader

Powerful UHF Reading and Writing

Wearable RFID Reader

Boost Efficiency with Hands-free UHF Data Capture

Wearable RFID Reader

Robust RFID Reading and Writing

Desktop RFID Reader

Professional Short Range RFID Reading, Tailored for Desktop Applications

Bluetooth RFID Reader

Outstanding UHF Capability

Fixed RFID Readers

Product Model- R3S Desktop RFID Reader

- URA4 Fixed RFID Reader (Android 9)

- URA4 Fixed RFID Reader (Android 13)

- UR4 Fixed RFID Reader

- UR8 Fixed UHF RFID Reader

- UR1A Integrated RFID Reader

- U300 Fixed RFID Reader (Android 11)

- R3 Desktop RFID Reader

- R1 RFID Reader/Writer

- Ant-RC05 5dBi Panel Antenna

- Ant-RC09 9dBi Panel Antenna

- Ant-RC12 12dBi Panel Antenna

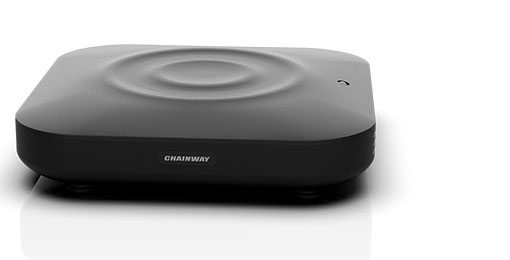

Desktop RFID Reader

Compact in Form. Flexible in Deployment. Built for Your Setup.

Fixed RFID Reader (Android 9)

Excellent RFID Capability with Suitable Android OS & Various Interface

Fixed RFID Reader (Android 13)

Excellent RFID Capability with Suitable Android OS & Various Interface

Fixed RFID Reader

Outstanding UHF RFID Performance

Fixed UHF RFID Reader

More Ports, Superior Performance, Perfect for Complex Deployments

Integrated RFID Reader

Integrated Design, Superior UHF RFID Performance

Fixed RFID Reader (Android 11)

Android 11 OS, Multiple Interfaces, More Powerful UHF RFID Performance

Desktop RFID Reader

Professional Short Range RFID Reading, Tailored for Desktop Applications

RFID Reader/Writer

Supports Multiple Protocol Standards With Excellent HF&UHF Performance

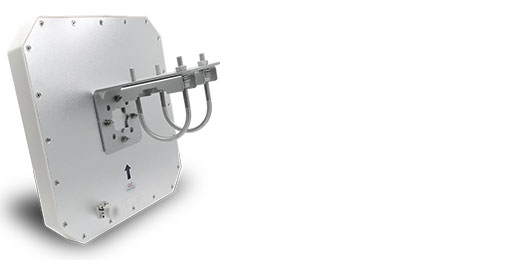

5dBi Panel Antenna

Being Portable and Compact, with Its Superior Performance

9dBi Panel Antenna

Environmental Adaptability, Easy Installation

12dBi Panel Antenna

With Outstanding UHF Performance, It Can Meet Various Applications

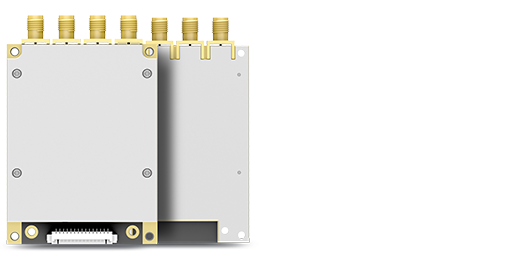

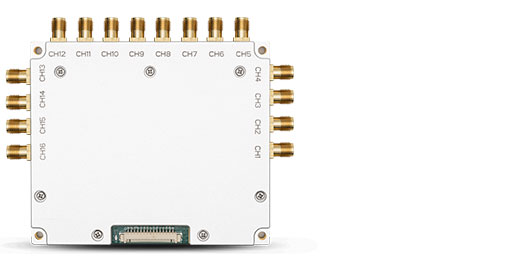

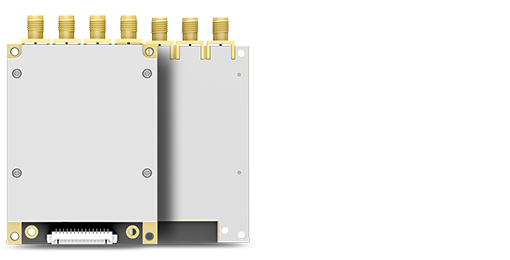

RFID Modules

Product Model- CM710-1 UHF RFID Module (1-Port)

- CM510-1 UHF RFID Module (1-Port)

- CM310-1 UHF RFID Module (1-Port)

- CM710-4 UHF RFID Module (4-Port)

- CM710-8 UHF RFID Module (8-Port)

- CM710-16 UHF RFID Module (16-Port)

- CM-5N UHF RFID Module (1-Port)

- CM-3N UHF RFID Module (1-Port)

- CM2000-1 UHF RFID Module (1-Port)

- CM2000-4 UHF RFID Module (4-Port)

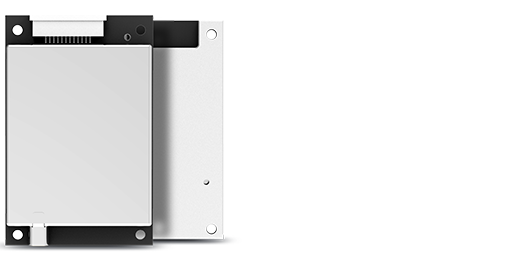

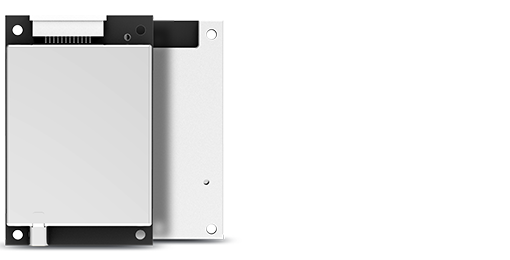

UHF RFID Module (1-Port)

Based on Impinj E710, 57.2 x 36.8 x 7.6 mm

UHF RFID Module (1-Port)

Based on Impinj E510, 57.2 x 36.8 x 7.6 mm

UHF RFID Module (1-Port)

Based on Impinj E310, 57.2 x 36.8 x 7.6 mm

UHF RFID Module (4-Port)

Based on Impinj E710, 77.2 x 51.0 x 8.9 mm

UHF RFID Module (8-Port)

Based on Impinj E710, 93.0 x 79.8 x 8.9 mm

UHF RFID Module (16-Port)

Based on Impinj E710, 112.2 x 88.6 x 8.8mm

UHF RFID Module (1-Port)

Based on Impinj E510, 31.0 x 19.0 x 3.1 mm

UHF RFID Module (1-Port)

Based on Impinj E310, 31.0 x 19.0 x 3.1 mm

UHF RFID Module (1-Port)

Based on Impinj Indy R2000 chip, 57.2 x 36.8 x 7.6 mm

UHF RFID Module (4-Port)

Based on Impinj Indy R2000 Chip, 77.2 x 51.0 x 8.9 mm

RFID Software

Product ModelRFIDlinked

RFID Data Collection, Printing, Tagging, EPC Compliance, and more.

Biometric Readers

Product ModelFingerprint Scanner (Android 11/13)

More Powerful, More Extensible, More Advanced in Every Way

Industrial Tablet (Android 13)

More Power, More Features and More Versatility

Industrial Tablet (Android 9)

8'' Screen & 8000mAh Battery, Abundant Functions Available

Biometrics Reader (Android 11/13)

Accurate Fingerprint Reading and Facial Recognition

Optical Fingerprint Scanner (Android 11/13)

Accurate Fingerprint Reading, Reliable Identity Verification

Fingerprint Scanner (Android 11/13)

Superior UHF Performance, Enhanced Security, More Ruggedness

Optical Fingerprint Tablet (Android 9)

8'' Screen & 8000mAh Battery, Abundant Functions Available

Printers

Product ModelBarcode Printer

Excellent Barcode Printing, Efficient and Easy to Operate

RFID Printer

Powerful RFID and Barcode Printing, Speedy and Highly Secured

Vehicle-mounted Computers

Product ModelVehicle Computer

Enable Flawless Fulfillment

Mobility Family

Keyboardemulator

Support Middleware Development, Promote Convenience

VelocityEmulator

Support Applications Migration Easily

SafeUEM

All-in-one Platform Management

-

Industries

Logistics

Chainway handheld computer gives you added visibility and increased fle...

Retail

Chainway retail solution solves existing issues faced by retailers with...

Healthcare

Chainway mobile healthcare PDA captures accurate healthcare data in rea...

Finance

Chainway banking solution enables administrators to have real-time moni...

Warehousing

Chainway makes your warehouse connected and smart with its barcode/RFID...

Livestock

With Chainway PDAs, an errorless electronic profile of each animal is a...

Energy

Chainway PDAs integrated with custom-made function modules realize auto...

- Case Studies

- Our Partners

- Support

- About Us